IVDR Technical Documentation Sampling

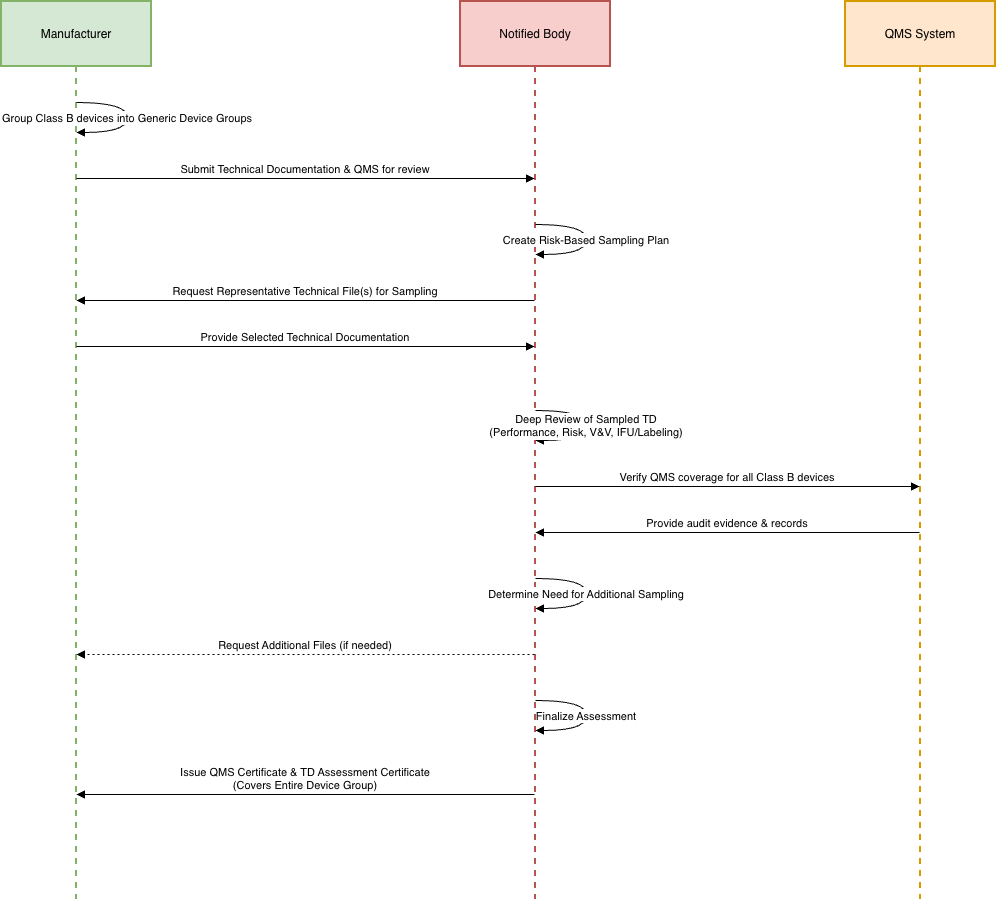

Typical Process for Technical Documentation (TD) Sampling for Assessment

Under EU IVDR 2017/746, Notified Bodies apply a structured sampling process to review Technical Documentation for devices covered under a manufacturer’s quality management system certificate. The goal is to ensure consistent compliance, product safety, and performance across the manufacturer’s full device portfolio. A typical sampling process includes the following steps:

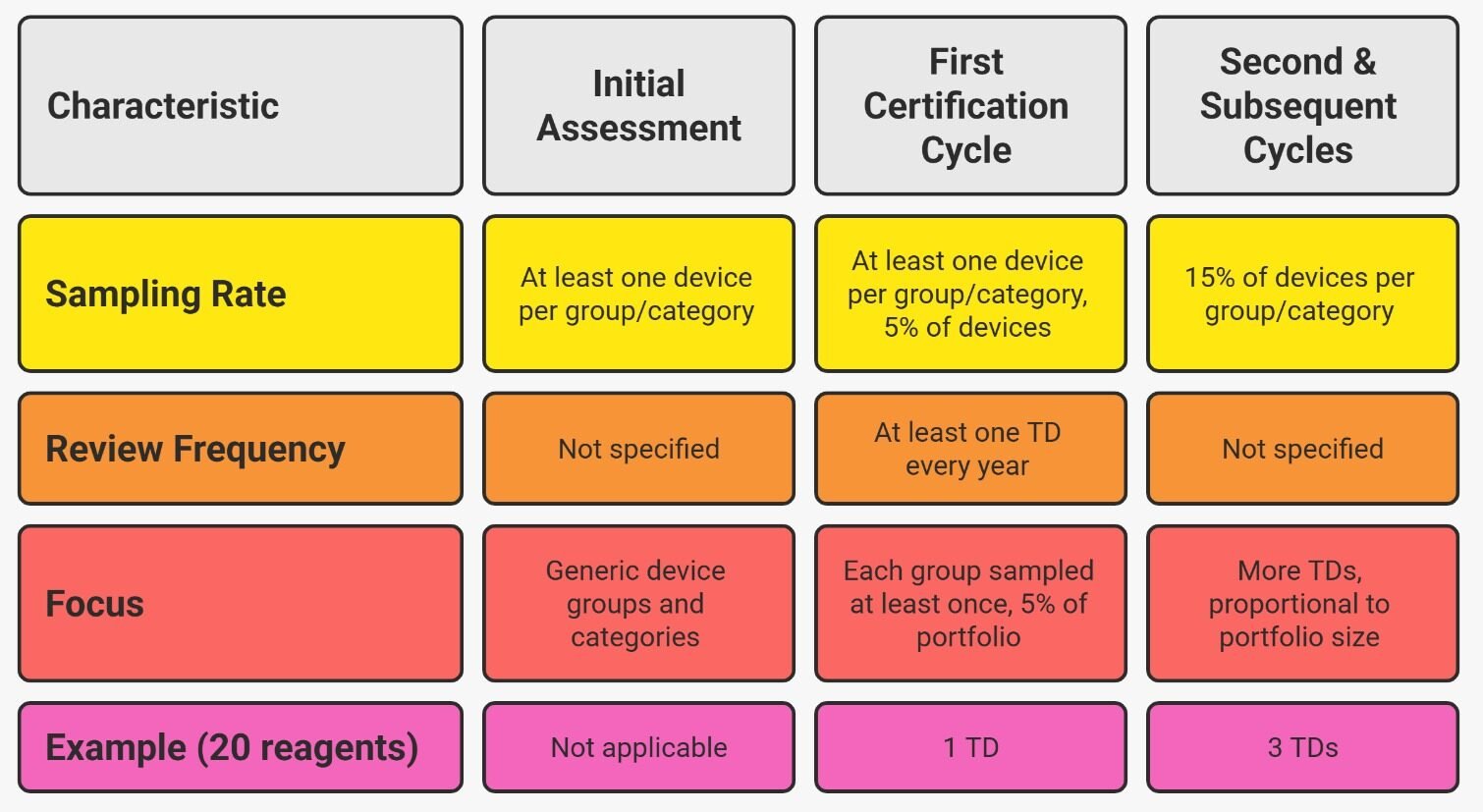

Before certification (Initial Assessment)– At least one device per generic device group and device category must be sampled before issuing the QMS certificate.

What it means: Your product portfolio must be grouped logically by:

- Device category (e.g., clinical chemistry, immunoassay, infectious disease).

- Generic device group within that category (e.g., lipid profile reagents, liver function reagents).

- The NB selects at least 1 TD from each group and category.

During surveillance within the first certification cycle:

During the first 5-year certification cycle, NB must:

- Sample at least one device per generic device group and device category

- Sample 5% of devices within each generic device group/category

- Review at least one TD every year

What this means in practice:

- If a generic device group contains 20 reagents, the NB will not review all 20, but 5% of them: 5% of 20 = 1 TD

- If another group contains 60 devices: 5% of 60 = 3 TDs

- However, NB does not need to repeat sampling of the same group if it was already reviewed during initial certification, unless risk or PMS triggers it.

Example: Suppose a manufacturer has 100 clinical chemistry reagents across 10 generic groups.

- NB already sampled 10 groups during certification

- During surveillance years:

- NB needs to ensure each group was sampled at least once

- Each year, NB must review at least 1 TD

- Total TDs during the full cycle = about 5% of portfolio, not all TDs

So, for 100 devices → 5% = 5 TDs over 5 years. Roughly 1 TD per year.

During Surveillance – Second & Subsequent Certification Cycles

Rule: Same principles as the first cycle, but sampling increases from 5% → 15% of devices per generic group/category.

What this means: Once certificate is renewed (2nd cycle):

- NB assesses more TDs because manufacturer has been on the market longer

- % increases for each generic group/category.

Example: If one generic group contains 20 reagents:

- First certification cycle: 5% = 1 TD

- Second certification cycle: 15% = 3 TDs

If the portfolio expands, sampling expands proportionally.

| Stage | % of TDs sampled | Minimum TDs per category/group | Minimum per year |

| Before Certification | Based on groups | 1 TD per generic group and device category | — |

| Surveillance – 1st Cycle (Years 1–5) | 5% | Ensure each group sampled once across cycle | ≥ 1 TD/year |

| Surveillance – 2nd & later cycles | 15% | Same group rule applies | ≥ 1 TD/year |

Importance of Annual Technical Documentation Updates

Annual updates are essential because:

-

New performance evaluation data must be incorporated

-

PMS and PMPF generate ongoing evidence every year

-

Analytical and clinical performance requirements evolve

-

New Common Specifications and standards may apply

-

Market feedback, complaints, and vigilance issues must be reflected

-

Version control and traceability are mandatory under IVDR

Regular updates reduce the risk of non-compliance during surveillance or sampling reviews.